I maxed out my 2020 MacBook Air M1 (A2337) with originally 512GB (2x256GB) storage to 2TB (2x1TB) for about 140 EUR and two hours of work. Considering such an upgrade would have cost more than 800 EUR back in 2020 (and officially only possible when purchasing a new Mac), the DIY upgrade was worth every cent and second ;) The 2TB option btw. nowadays costs 1000 EUR.

The 2020 MacBook Air M1 is still my favourite machine. It’s super silent, the battery lasts a full day of working (mostly in the terminal, no AI or other shit** and it’s very portable. I am glad that it’s possible to do such upgrades even though Apple loves to glue and solder everything in more and more products.

This post is a summary of the most important things and my personal experience regarding the NAND upgrade including a bunch of resources for more details and further reading. Whatever you do, you do it on your own risk! During the process, all data will be lost and the Mac can be permanently damaged. A backup is mandatory if you want to keep even a single bit of the original NAND.

I highly recommend reading everything here before even purchasing a BGA knife! You will need patience, tools, steady hands, improvisation and maybe a new Mac afterwards.

Resources

I went through a lot of scattered information on the web and distilled it into a few links, listed below. Together with my write-up, the rest depends on your skills to successfully upgrade a Mac.

- There is an excellent video about the whole upgrade process by

dosdude1on YouTube: Upgrading Apple Silicon Soldered SSDs - The Apple Silicon Soldered SSD Upgrade Thread on MacRumors is a great collection of information

- There is a new project which takes the NAND replacement to a new level: a breakout PCB board which allows to swap NANDs easily. Here is the promotional video: No More Storage Limits and the website (not affiliated): MacBook Modification Kit

- A good NAND Programmer if you can’t find and source any blank NAND chips or need to reprogram them is the P13 (or newer versions) from JCID: JCID NAND Read & Write Programmer

Basics

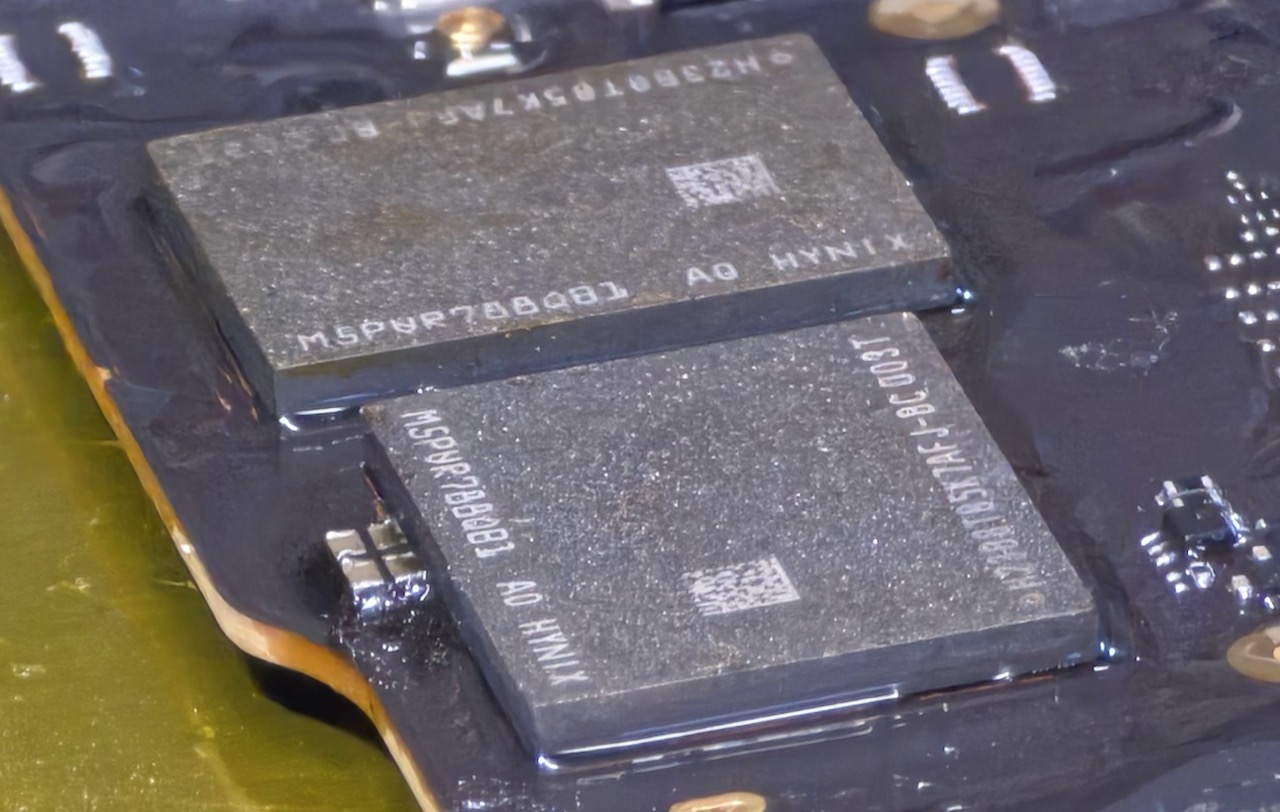

iPhones, iPads and almost all Macs nowadays use one or two NAND chips as main storage. The SSD controller itself is directly integrated into the Apple Silicon SoC (M1, M2, etc.). This means that the CPU itself is the NAND manager and does error correction, wear levelling and encryption. When upgrading the storage of such a device, only the NAND chip(s) are replaced. After the replacement, they need to be restored/formatted by putting the device into DFU mode and connecting it to another Mac (with the same CPU type, according to various sources I found) using a USB-C cable. The whole process can be done with the Apple Configurator, available at the Mac App Store.

A side note on the used NAND chips: the chips are coming in a surface-mount packaging which is a ball grid array (BGA). This means that instead of pins, the chip has flat circular pads on the underside which look like small balls when solder is applied due to the surface tension of the solder itself. The solder is applied in form of a paste using a stencil with a matching BGA footprint.

What you need…

Here is a list of the tools you’ll need. Depending on your skills, you’ll need

more or less ;) The Amazon links are affiliate links, if you purchase the

products using the link, you support me a tiny bit.

- Mac with preferable two existing NAND chips. These are typically the models with more than 256GB. The 128GB version has only one NAND chip on the board, the other pad is unpopulated and there are plenty of capacitors and resistors missing too on the other side of the board. It’s doable but much more work, which involves soldering as small as 0201 SMD components.

- Hot air gun: a decent one which can reach about 400°C

- Soldering iron, e.g. my favourite: TS101

;)Amazon - Leaded solder and solder paste - unleaded works too, but requires much more experience

- Solder flux Amazon

- BGA Stencil for the NAND footprint (BGA110 in case of the M1 and M2 Macs). You can find them on AliExpress, Amazon etc.

- Desoldering wick Amazon

- Precise tweezers, I prefer those from Bernstein Amazon

- Kapton tape Amazon

- PCB preheater Amazon

- BGA knife - a thin, elastic blade and a precise hook to remove the underfill and get under the NAND when desoldering Amazon

- Screwdrivers (T3, T4, T5, Pentalobe). iFixit has very nice tools, if you don’t have a set, I recommend something like this e.g. on Amazon

Procedure

Below is a step-by-step procedure for the NAND replacement. Make sure to read everything before you start.

Take out the logic board (iFixit.com has beautiful tutorials)

Remove any tiny rubber or plastic space holders near the NANDs since they will melt otherwise

No flux for the next steps!

No flux! Heat the NANDs (one-by-one) to 350°C and then remove the underfill around them with a fine hook

No flux! Make sure that you remove the underfill on each side (also the corners), otherwise it will be very hard to lift them off

No flux! Increase the heat to 380-390°C (I had to go even above 415°C) and gently try to get under the chip on one of the sides were no components are in the way. The thin knife should feel like a knife through cold butter. This process can take several minutes when the temperature is not high enough. Use a hot air nozzle with at least 1cm diameter. If you can’t get underneath the chip, slightly increase the heat.

No flux! Lift off the NAND

No flux! Scrape away the underfill and the solder on the board at 380°C with a flat scraper (small angle, below 45deg). Still no flux, otherwise the underfill will become a messy glue!

Now use flux and leaded solder first to mix up the unleaded solder on the pads

Remove the solder using a soldering iron and desoldering wick

Clean the board with isopropyl alcohol

Use the BGA stencil to apply solder paste on the pads. First, align the NAND, then secure it with Kapton tape. After that, use a wide blade to push the solder paste into the stencil holes.

Use hot air at around 330°C to create nice and equally sized solder balls, while the stencil is still on the chip. Here is a picture showing the stencil on top of the NAND. The solder paste has been applied and heated beyond its melting point.

Remove the stencil, apply some flux and reball again with 330°C

Preheat the board to around 180°C (I did it with only 80°C because I only had a preheat bed, without a hot air blower)

Apply solder flux to the pads, place the chips on and solder them with 330°C using the hot air gun. If everything goes well, the chips should settle down when the solder balls melt and a very slight touch with the tweezers (while still applying heat) should move the chip a tiny little bit and it should snap back to the correct position again when untouched.

Put everything together but do not connect the battery yet and do not mount the bottom cover

Place the Mac so that the screen shows up and the bottom half is vertical, so that you can reach the back side of the logic board

Connect the Mac to another Mac with the same CPU type using a USB-C cable. Use the primary USB-C port (the one closer to the back edge) on the Mac which you upgraded. The other USB-C port on the host Mac can be any

Start Apple Configurator, you will see a screen waiting for device to be connected

Enter DFU mode on the upgraded Mac by using fine tweezers to short the two pads on the picture and while shorting them, plug in the charger in the secondary USB-C (the one further from the back edge). Note that there are plenty of resources in the Internet (including Apple’s How to revive or restore Mac firmware) which explain how to enter DFU mode, but those methods will not work because the Mac is now in a boot-loop, which makes it practically impossible to perform any kind of key-combo gymnastics. The tweezers method described by

dosdude1in his Upgrading Apple Silicon Soldered SSDs at33:23works perfectly fine.

A big DFU text should now appear in the Apple Configurator. Right-click and restore

This process takes about 20-30 minutes and ends when the Mac reboots and shows an unconnected battery symbol

Now attach the battery while still everything is connected

Press the touchpad or some keys and the Mac should boot and finish the restore procedure in Apple Configurator

Disconnect everything and restore your backup!

Result

It works ;) Black Magic Disk Speed Test reports roughly 3GB/s write and

2.8GB/s which is 10% faster than the original 2x256GB NAND chips!

Remarks

- Mark the original NANDs, so that they can be placed back when something goes wrong with the new ones. Those might be faulty or damaged during the process. The NANDs must not swap places, once they are configured.

- Getting the NANDs off can be really difficult. If you can’t get underneath the NAND with the BGA knife, increase the heat instead of the force! The components can tolerate fairly high temperatures.

- The NAND pads on the logicboard should be clean! There is a risk that the solder pads will not connect correctly (or even connect to their neighbours) when there is leftover solder, underfill or other dust and dirt.

- Only the NAND chips is soldered up and the solder balls should all have the same size. If you spot any solder balls which seem to be larger or smaller compared to the rest, remove all the solder using flux with solder wick, clean everything with ispropyl alcohol, let the chip cool down (otherwise the solder paste will turn into liquid and flow underneath the BGA stencil!), reapply the solder a and reball. Repeat until it’s perfect!

- Entering the DFU mode is really easy but you need to have very fine tweezers.

Where to buy NANDs and stencils?

I bought two 1TB chips (in July 2025) on

AliExpress.com for 150 EUR including the BGA stencil

and shipping to Germany. Here is the link to the product page (not affiliated!):

https://de.aliexpress.com/item/1005008184256402.html.

For the M1 MacBook, I used the search term KICM223, which is one of the more

common chips (from Kioxia) circling around. I eventually received the H23B8T85

from Hynix.

Generally, it’s not so easy to figure out what type the chips are and I had to

trust the description. People who sell these often have little technical

knowledge about the components. I contacted the seller but did not receive any

message back. However, everything was fine in the end ;)

Make sure to buy blank NANDs chips! Otherwise you’ll need a programmer. Technically, only the master NAND (of each channel) needs to be blank, but I’d not gamble.